Real-Time Inventory

Replaced spreadsheets with a single real‑time inventory view across locations, so teams could trust stock counts and meet enterprise expectations for integrated inventory. MVP shipped Dec 2024.

Phase 1 · Understand

Problem

- Users: Teams needed accurate stock counts without hours of reconciliation; otherwise projects slipped and equipment went missing

- Stakeholders: Enterprise prospects expected integrated inventory before signing deals

Objectives

- Reduce manual tracking and errors

- Automate alerts and reorders

- Integrate with purchasing/projects

Research Insights

- Methods: 6 user interviews, workflow mapping, and a competitive analysis

- Time sink: 2–3 hours/day reconciling stock; 15–20% error rates

- User split: Small AV shops needed fast confidence in quantities, while larger teams needed asset‑level traceability (tracking specific asset numbers) for accountability

- Market signal: Integrated inventory was table stakes in enterprise deals

Phase 2 · Decide

Solution Journey

Problems

- Manual spreadsheet reconciliation hid low‑stock thresholds, causing delays and last‑minute emergency buys

How Might We

How might we surface critical inventory risks and eliminate manual reconciliation?

Solutions

- Surface risk: Visual low-stock and incoming-PO indicators on the inventory dashboard

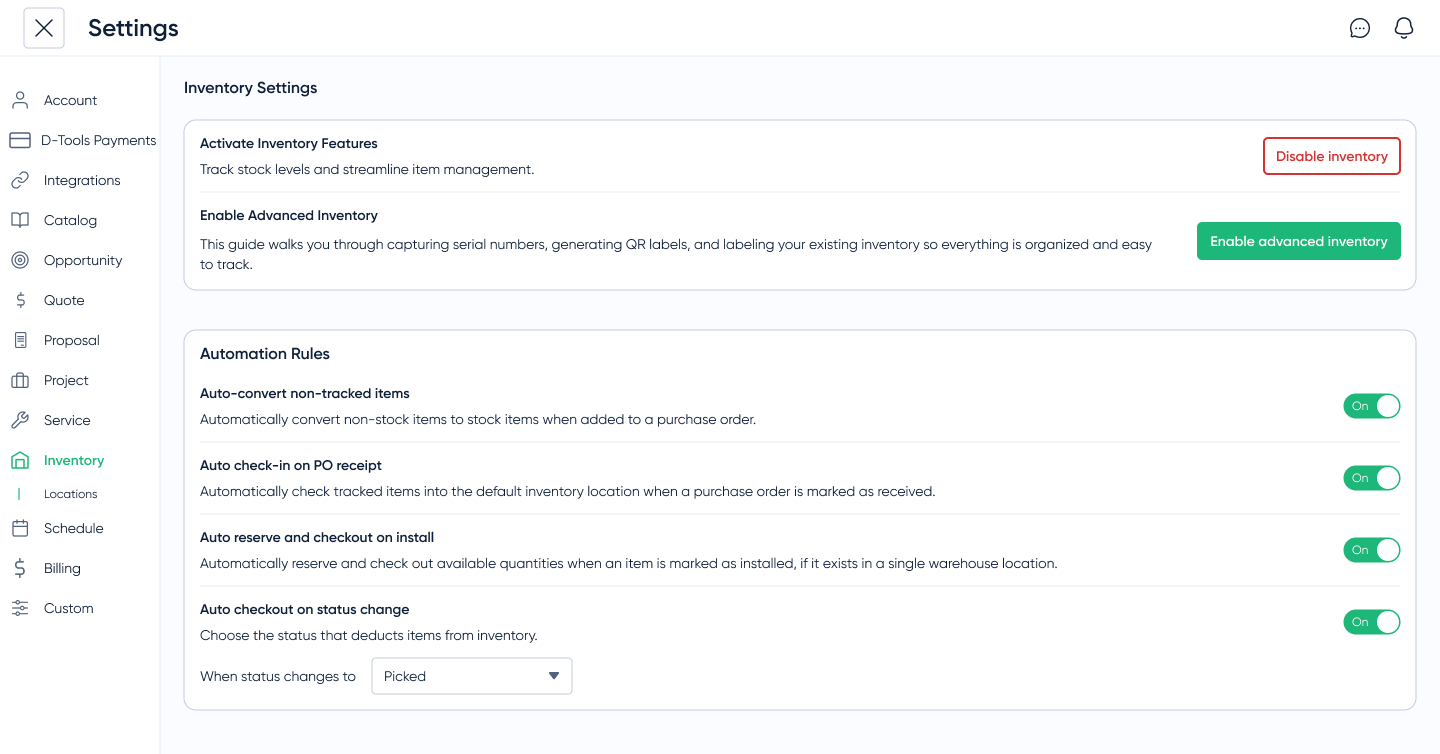

- Automation: PO-driven stock updates and status changes across locations

Key decisions & tradeoffs

- Real-time, unified model: Chose real-time inventory with a single data model for project and stock views. This increased technical complexity and required early engineering collaboration, but gave all locations the same numbers and eliminated duplication

- Manual reordering MVP: Launched manual reordering with alerts to validate workflows quickly, deferring auto-PO generation to Phase 2

- Native integration: Chose integration with Cloud purchasing and project tools over a standalone module. This increased initial scope but met enterprise needs and reduced tool sprawl

Design Highlights

Prototyping & Validation

Ran three rounds of high‑fidelity Figma tests to validate receiving, alerts, multi‑location inventory, and reordering flows for clarity and error reduction.

The key learning: one system, two operating modes

Early concepts assumed every team needed asset‑level tracking everywhere. Testing and stakeholder feedback made the split obvious: smaller AV shops mostly needed quick confidence in quantities, while larger teams needed to track specific asset numbers for accountability. I adjusted the information architecture to be quantity‑first by default, with asset‑level detail available when teams needed it—so the system stayed powerful without overwhelming smaller teams.

Quality & Handoff

- Edge‑case coverage: Documented how allocations, multi‑location states, and receiving/reordering rules affect “available” inventory so UI behavior stays consistent

- Shared data model: Aligned with engineering on how locations, allocations, and asset‑level tracking roll up into one source of truth for stock counts

Impact

Reduced material waste and improved project accuracy—one customer uncovered “thousands of dollars of unused equipment.”

Phase 4 · Forward Thinking

Next Steps

- MVP lesson: Ship the “PO received” loop first to build trust, then layer automation

- Next: auto-PO creation from thresholds, mobile scanning, and stock analytics (velocity and dead stock)